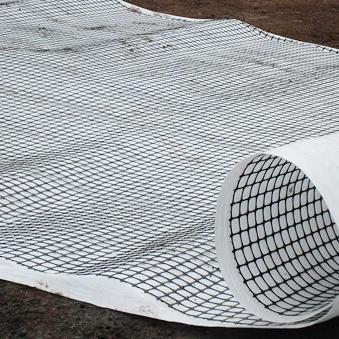

LLDPE Geomembrane

LLDPE geomembrane is a type of geomembrane that is made from linear low-density polyethylene (LLDPE). LLDPE is a synthetic polymer that is known for its strength, durability, and flexibility. It is also resistant to chemicals, UV radiation, and tears.

- Commodity name: LLDPE Geomembrane

Delivery Time

10-15 days after receiving payment

Delivery Method

Send in the best possible way

Delivery Time

Usually 15-30 days

- Product Description

-

What is LLDPE geomembrane?

LLDPE geomembrane is a type of geomembrane that is made from linear low-density polyethylene (LLDPE). LLDPE is a synthetic polymer that is known for its strength, durability, and flexibility. It is also resistant to chemicals, UV radiation, and tears.

What is the specification of LLDPE geomembrane sheet?

The specification of LLDPE geomembrane sheet can vary depending on the manufacturer and the application. However, there are some general specifications that are common to most LLDPE geomembrane sheets.Width:1-8m

Length:50-150m as customized

Thickness:0.2mm-3.0mm

Color:Black, white,customized products can be supported according to customer needsHere are some of the key specifications for LLDPE geomembrane sheet:

Thickness: LLDPE geomembrane sheets are typically available in thicknesses ranging from 0.2 mm to 3 mm. The thickness of the geomembrane will affect its strength, durability, and resistance to puncture.

Tensile strength: LLDPE geomembrane sheets have a high tensile strength, which means that they can withstand a lot of force without tearing. The tensile strength of the geomembrane will affect its ability to resist tearing and puncture.

Elongation: LLDPE geomembrane sheets have a high elongation, which means that they can stretch a lot without breaking. The elongation of the geomembrane will affect its ability to deform without tearing.

Tear strength: LLDPE geomembrane sheets have a high tear strength, which means that they can withstand a lot of force without tearing. The tear strength of the geomembrane will affect its ability to resist puncture.

Chemical resistance: LLDPE geomembrane sheets are resistant to a variety of chemicals, including acids, bases, and solvents. The chemical resistance of the geomembrane will affect its ability to withstand exposure to chemicals.

UV resistance: LLDPE geomembrane sheets are resistant to UV radiation, which means that they can withstand exposure to sunlight without breaking down. The UV resistance of the geomembrane will affect its ability to withstand exposure to sunlight.In addition to these key specifications, LLDPE geomembrane sheets may also have other specifications, such as:

Temperature range: LLDPE geomembrane sheets are typically designed to operate in a temperature range of -40°C to 80°C. However, some LLDPE geomembrane sheets can operate in a wider temperature range.

Water vapor transmission rate: LLDPE geomembrane sheets have a low water vapor transmission rate, which means that they are good at preventing water vapor from passing through them. This can be important in applications where it is important to prevent moisture from accumulating.

Fire rating: LLDPE geomembrane sheets are typically classified as Class B fire retardant. This means that they will not readily catch fire and will not contribute to the spread of fire.

The specific specifications for LLDPE geomembrane sheet will depend on the manufacturer and the application. It is important to consult with the manufacturer to determine the specific specifications that are required for your application.What are the applications of LLDPE geomembrane?

Landfill liners: LLDPE geomembranes are used as liners in landfills to prevent the migration of leachate, which is the liquid that seeps through waste in a landfill.

Wastewater containment: LLDPE geomembranes are used to contain wastewater in ponds, lagoons, and other structures.

Erosion control: LLDPE geomembranes are used to control erosion in waterways, shorelines, and other areas.

Rooftop membranes: LLDPE geomembranes are used as roofing membranes to prevent leaks and to provide insulation.

Dams and levees: LLDPE geomembranes are used in dams and levees to prevent the seepage of water.

Aquatic habitats: LLDPE geomembranes are used to create artificial aquatic habitats, such as fish ponds and wetlands.

LLDPE geomembranes are also used in a variety of other applications, such as:

Chemical storage: LLDPE geomembranes are used to store chemicals because they are resistant to a variety of chemicals.

Agriculture: LLDPE geomembranes are used in agriculture to control erosion and to store water.

Construction: LLDPE geomembranes are used in construction to prevent the seepage of water and to provide insulation.

The specific application of LLDPE geomembrane will depend on the specific requirements of the project. It is important to consult with a geotechnical engineer to determine the right application for your project.

LLDPE Geomembrane has a number of key performance features, including:

Strength and durability: LLDPE Geomembrane is strong and durable, making it a reliable solution for a variety of projects. It can withstand high loads and pressures without tearing or deforming.

Chemical resistance: LLDPE Geomembrane is resistant to a variety of chemicals, making it ideal for applications where it may come into contact with hazardous materials.

UV resistance: LLDPE Geomembrane is resistant to UV radiation, making it a good choice for applications where it will be exposed to sunlight.

Tear resistance: LLDPE Geomembrane is tear resistant, making it a good choice for applications where it may be subjected to high winds or other forces that could cause tearing.

Lightweight and easy to install: LLDPE Geomembrane is lightweight and easy to install, making it a cost-effective solution for a variety of projects.

LLDPE Geomembrane is a reliable and cost-effective solution for a variety of projects. It is strong, durable, and resistant to a variety of environmental factors. It is also lightweight and easy to install.If you are looking for a high-performance geomembrane for your next project, LLDPE Geomembrane is a great option. It is a reliable and cost-effective solution that can help you protect your assets and the environment.

Properties

Test

Test Value

Testing Frequency

Method

0.50mm

0.75mm

1.0mm

1.25mm

1.50mm

2.00mm

2.5mm

3.0mm

(minimum)

Thickness-mm(min.ave.) D5199

nom.

-10%nom.

-10%nom.

-10%nom.

-10%nom.

-10%nom.

-10%nom.

-10%nom.

-10%per roll

lowest individual of 10 values Density g/ml (max.) D1505/D792

0.939

0.939

0.939

0.939

0.939

0.939

0.939

0.939

90,000 kg

Tensile Properties (1)(min.ave.) D6693

9,000 kg

break strength – N/mm TypeIV

13

20

27

33

40

53

66

80

break elongation -% 800

800

800

800

800

800

800

800

2% Modulus – N/mm (max.) D5323

210

315

420

520

630

840

1050

1260

per formulation

Tear Resistance - N (min.ave.) D1004

50

70

100

120

150

200

250

300

20,000 kg

Puncture Resistance - N (min.ave.) D4833

120

190

250

310

370

500

620

750

20,000 kg

Axi-Symmetric Break Resistance Strain-%(min.) D5617

30

30

30

30

30

30

30

30

per formulation

Carbon Black Content-% D4218(3)

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

2.0-3.0

20,000 kg

Carbon Black Dispersion D5596

note(3)

note(3)

note(3)

note(3)

note(3)

note(3)

note(3)

note(3)

20,000 kg

Oxidative Induction Time (OIT) (4) 90,000 kg

(c)Standard OIT (min.ave.)—or— D3895

100

100

100

100

100

100

100

100

(d)High Pressure OIT (minave) D5885

400

400

400

400

400

400

400

400

Oven Aging at 85°C (5) D5721

per formulation

(a)Standard OIT (min.ave.) - % retained after 90 days—or— D3895

35

35

35

35

35

Key words:

LLDPE Geomembrane

Factory Appearance

The main products include HDPE geomembrane, HDPE high-density geomembrane, LDPE geomembrane, smooth geomembrane, rough geomembrane, composite geomembrane, column geomembrane, liner geomembrane, waterproof board, geotextile, geogrid, bentonite synthetic blanket and other geosynthetics.

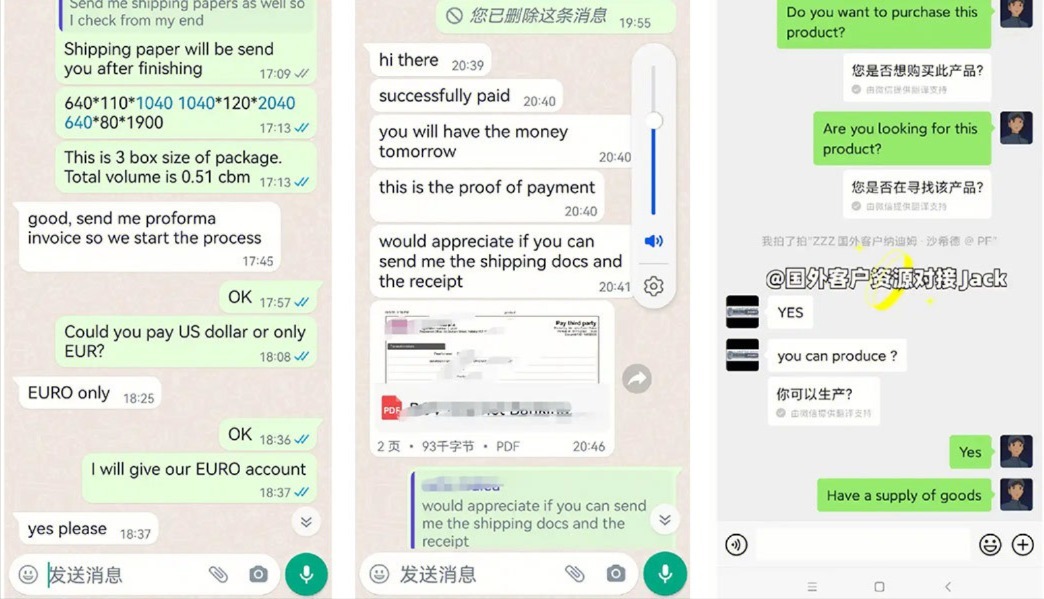

Packaging And Delivery

Our annual output has exceeded 300 million square meters, with our main markets being South America, Australia, parts of Asia and Africa, and our products are exported to more than 40 countries. We not only guarantee stable production capacity and on-time delivery, but also have professional technical workers and are constantly improving product quality to meet customer needs.

Application Cases

These products have been widely used in more than 300 projects in the fields of environmental protection, expressways, railways, golf courses, etc. The company has accumulated rich engineering experience. It enjoys a reputation of "good quality and high standard" in the industry, and has received unanimous praise from the engineering community and a large number of users. Moreover, it has established close cooperative relationships with dozens of scientific research and design units and universities across the country.

Customer visit

The company always adheres to the business philosophy of "science and technology first, integrity-based, and win-win coexistence", and sincerely hopes to cooperate extensively with friends at home and abroad to jointly draw a magnificent blueprint!

Customer Feedback

WHY CHOOSE US

High Cost Performance

High quality products and great prices.

Guarantee Quality

Product quality meets international quality inspection standards.

Advanced Equipment

We have introduced the latest production equipment.

Good Service

We have a professional team to serve you.

FAQ

About product prices?

Can you send samples?

How long is your delivery time?

How many SQM of one container can load?

Can I go to your factory to visit?

What is the roll width of your Geotextile Geomembrane ?

Product Consulting