Composite Geomembranes: Your Ultimate Shield Against Water Intrusion

Release time:

2025-10-08

Composite Geomembranes: Your Ultimate Shield Against Water Intrusion Table of Contents 1. Introduction to Composite Geomembranes 2. What Are Composite Geomembranes? 3. Advantages of Composite Geomembranes 4. Key Applications of Composite Geomembranes 5. Installation Techniques for Composite Geomembranes 6. Maintenance and Care for Longevity 7. Environme

Composite Geomembranes: Your Ultimate Shield Against Water Intrusion

Table of Contents

- 1. Introduction to Composite Geomembranes

- 2. What Are Composite Geomembranes?

- 3. Advantages of Composite Geomembranes

- 4. Key Applications of Composite Geomembranes

- 5. Installation Techniques for Composite Geomembranes

- 6. Maintenance and Care for Longevity

- 7. Environmental Impact of Composite Geomembranes

- 8. Cost Considerations for Using Composite Geomembranes

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. Introduction to Composite Geomembranes

In the realm of construction and landscaping, the importance of effective water management cannot be overstated. Water intrusion can lead to severe damage to structures, landscapes, and the environment. To combat this challenge, industry professionals are increasingly turning to composite geomembranes. These specialized materials provide an unmatched barrier against water infiltration, ensuring the integrity and longevity of construction projects.

This article delves deeply into composite geomembranes, exploring their composition, advantages, applications, installation, and long-term maintenance.

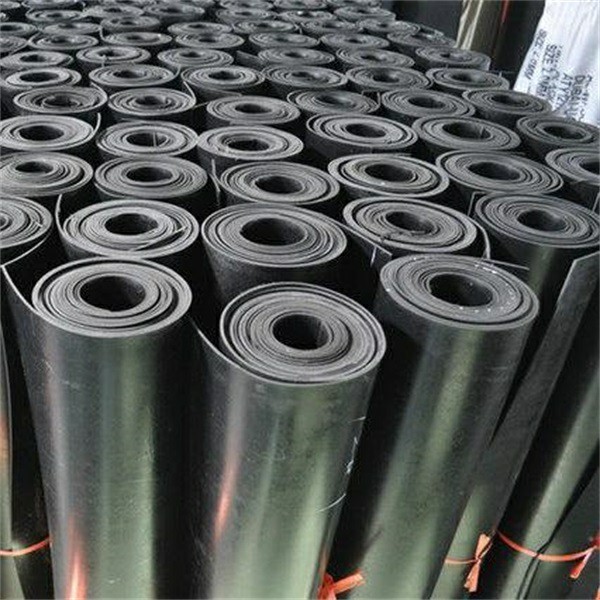

2. What Are Composite Geomembranes?

Composite geomembranes are impermeable membranes used primarily in civil engineering applications to prevent the migration of fluids. They are typically made from a combination of materials, often including high-density polyethylene (HDPE) or polyvinyl chloride (PVC) faced with a protective layer, which enhances their durability and resistance to punctures and environmental conditions.

This composite structure allows for improved performance compared to traditional geomembranes, making them an ideal choice for various applications. The design not only contributes to their waterproofing capabilities but also provides additional benefits such as UV resistance, chemical stability, and mechanical strength.

2.1 Construction of Composite Geomembranes

The construction of composite geomembranes typically involves layering different materials. For example, an HDPE layer can be combined with a non-woven geotextile fabric, providing both impermeability and additional structural support. This multi-layered approach allows for customized solutions to suit specific project needs, ensuring maximum effectiveness against water intrusion.

2.2 Key Materials Used

- **High-Density Polyethylene (HDPE):** Known for its robustness and chemical resistance, HDPE is a popular choice for geomembranes.

- **Polyvinyl Chloride (PVC):** Flexible and versatile, PVC is often used in areas requiring easy handling and installation.

- **Geotextiles:** These fabrics enhance the mechanical properties of geomembranes, improving durability and puncture resistance.

3. Advantages of Composite Geomembranes

The numerous advantages of composite geomembranes make them a preferred choice for many construction and landscaping projects.

3.1 Superior Water Resistance

The primary function of composite geomembranes is to provide a reliable barrier against water intrusion. Their impermeable nature ensures that water does not penetrate through the barrier, protecting structures and landscapes from potential damage.

3.2 Enhanced Durability

Composite geomembranes are designed to withstand harsh environmental conditions. Their resistance to UV radiation, extreme temperatures, and chemical exposure extends their lifespan, reducing the need for frequent replacements.

3.3 Cost-Effectiveness

While the initial investment in composite geomembranes may be higher than traditional options, their long-term benefits significantly outweigh the costs. Their durability and low maintenance requirements translate to significant savings over time.

3.4 Easy Installation

Composite geomembranes are relatively easy to install, thanks to their lightweight nature and flexibility. This reduces labor costs and allows for quicker project completion.

3.5 Environmental Benefits

Using composite geomembranes can help mitigate the environmental impact of construction activities. By preventing water pollution and promoting proper drainage, these geomembranes contribute to sustainable practices in the industry.

4. Key Applications of Composite Geomembranes

Composite geomembranes are versatile and can be utilized in various applications across different industries.

4.1 Landfills

In landfill construction, composite geomembranes serve as barriers, preventing leachate from contaminating groundwater. Their impermeable nature is crucial for maintaining environmental integrity.

4.2 Wastewater Treatment Plants

These geomembranes are used in wastewater treatment facilities to contain and manage fluids, ensuring that harmful substances do not infiltrate surrounding areas.

4.3 Agricultural Applications

In agriculture, composite geomembranes are employed for irrigation ponds, containment of fertilizers, and protecting soil structures from erosion.

4.4 Mining Operations

Mining companies use composite geomembranes to manage water runoff and tailings, thereby preventing water from entering sensitive ecosystems.

4.5 Water Reservoirs

In the construction of water reservoirs, these geomembranes help maintain water quality by preventing external contaminants from entering the water supply.

5. Installation Techniques for Composite Geomembranes

Proper installation of composite geomembranes is essential for maximizing their efficacy. The following steps outline the best practices for installing these materials.

5.1 Site Preparation

Before installation, it is essential to prepare the site by removing debris, sharp objects, and vegetation that could damage the geomembranes.

5.2 Material Handling

Transportation and handling should be done carefully to prevent any physical damage to the geomembranes. It is crucial to avoid excessive bending or folding.

5.3 Laying the Membrane

The geomembranes should be laid flat and overlapped according to manufacturer specifications. Proper alignment ensures maximum coverage and effectiveness.

5.4 Seaming Techniques

Seaming techniques, such as thermal welding or chemical bonding, should be employed to create strong joints. These seams must be tested for integrity before the project is considered complete.

5.5 Backfilling and Protection

Once installed, backfilling with soil or other materials may be necessary. Protective layers should also be considered to prevent puncturing and wear.

6. Maintenance and Care for Longevity

While composite geomembranes are designed to last, routine maintenance is essential to ensure their longevity and effectiveness.

6.1 Regular Inspections

Conducting regular inspections helps identify any issues, such as punctures or wear, before they become significant problems.

6.2 Cleaning and Debris Removal

Keeping the surface clean and free of debris can prevent deterioration and ensure the geomembranes function effectively.

6.3 Repair Techniques

Should damage occur, prompt repairs using compatible materials will help maintain the integrity of the geomembrane. Techniques may include patching or reseaming.

7. Environmental Impact of Composite Geomembranes

Composite geomembranes significantly contribute to environmental protection efforts.

7.1 Pollution Prevention

By preventing water contamination from leachates and runoff, these geomembranes play an essential role in protecting groundwater resources.

7.2 Resource Conservation

The use of composite geomembranes promotes resource conservation by ensuring efficient water management in various applications.

8. Cost Considerations for Using Composite Geomembranes

Understanding the cost implications of using composite geomembranes is crucial for project planning.

8.1 Initial Investment

The initial costs of composite geomembranes can be higher than traditional options, but their durability and longevity often justify the expense.

8.2 Long-Term Savings

The reduced need for maintenance and replacements can lead to significant long-term savings, making composite geomembranes a financially sound investment.

8.3 Budgeting for Installation

Proper budgeting for installation, including labor and material costs, is essential to avoid unexpected expenses during the project.

9. Frequently Asked Questions (FAQs)

9.1 What are the main benefits of using composite geomembranes?

The main benefits include superior water resistance, enhanced durability, cost-effectiveness, easy installation, and environmental protection.

9.2 How long do composite geomembranes last?

With proper installation and maintenance, composite geomembranes can last for several decades.

9.3 Are composite geomembranes environmentally friendly?

Yes, they help prevent water pollution and promote sustainable practices in construction.

9.4 Can composite geomembranes be repaired if damaged?

Yes, repairs can be performed using compatible materials and techniques to maintain their integrity.

9.5 What factors should be considered when choosing geomembranes?

Key factors include the specific application, environmental conditions, budget, and required durability.

10. Conclusion

Composite geomembranes serve as an essential shield against water intrusion, offering unparalleled protection for various construction and landscaping applications. Their combined benefits of durability, cost-effectiveness, and environmental protection make them a preferred choice for professionals in the industry. By understanding their advantages, applications, and maintenance requirements, you can ensure that your projects remain safeguarded against the adverse effects of water intrusion. Investing in composite geomembranes is not just a choice; it's a commitment to quality and sustainability in construction.

Previous Page